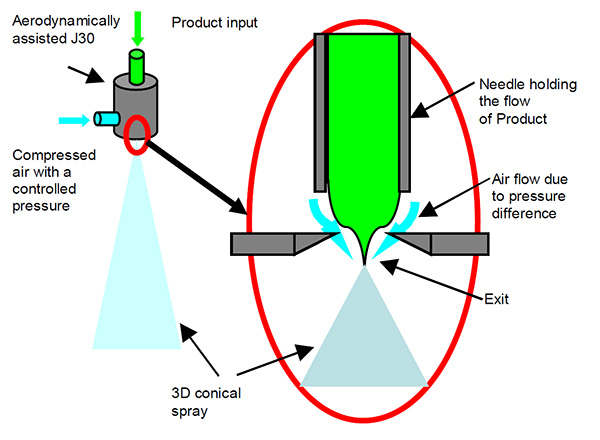

VARD2Go Thermal with Aerodynamic Nozzle

The aerodynamically assisted jetting equipment is showed on the figure below. The product enters through a central needle. The exit orifice, which is centrally in line with the axis of the needle, has been counter sunk externally. The counter sunk leads to the aero dynamical effect that the jet has the smaller diameter when it is passing the orifice than the needle. The needle is enclosed in a pressure chamber with an exit through the orifice. The size of the drops is determined by the product flow rate and the pressure inside the chamber. The product flow rate is typically controlled by a high precision syringe pump to be connected to the product nozzle. The pressure in the pressure chamber is controlled by the especially for the unit developed Nisco pressure control unit consisting of a pressure sensor with digital indication and a control cabinet with the pressure controller. The pressure set point can be fixed with a potentiometer.

The head of VARD2Go Thermal unit is equipped with a heating chamber, which includes an electrical heater (230V / 75W) and Pt-100 sensor to control the temperature. The air pressure vessel of the thermal aerodynamic option is also equipped with a heating chamber. The heating system is performed by electrical heater (110V / 75W) and a Pt-100 sensor to control the temperature.

|

During the work with very low pressure the drops won’t be produced, but there will be a laminar jet smaller than the nozzle applied. If the vibration would be superimposed the even sized beads down to half the size of the applied nozzle could be produced. Example: With laminar jet break-up you produce drops double the size of the used nozzle diameter. If you need smaller beads you can combine the laminar jet-break-up with aerodynamic nozzle and achieve a drop size of 200micrometers or even smaller with a 200micrometer nozzle. |

Remarks:

-

> The aerodynamic nozzles for vibrating units are available in the range of 100 to 350μm.

> An adapter for the VARJ30 coaxial nozzles is available on request!

> The VARD2Go Thermal unit is optionally equipped with a Mini Chiller Unit and a 3L double jacketed beaker, made from borosilicate, if the cooling down of hardening solution is needed.

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download VARD2Go Thermal with Aerodynamic Nozzle as PDF file |