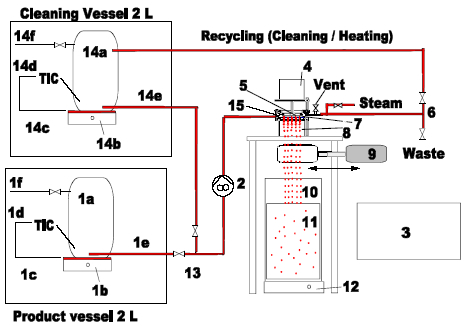

Var E Thermal:

Legend:

1a |

Stainless steel vessel (max. 6barg) | 8 |

Sightglass with stroboscopic light |

1b |

Magnetic laboratory agitator with agitation element | 9 |

Bypass system |

1c |

Heating plate | 10 |

Vessel with hardening solution |

1d |

Temperature controller with pT 100 | 11 |

Hardening solution with beads (for information) |

1e |

Heatable hose(electrical heating) | 12 |

Laboratory stirrer |

1f |

Two nozzles for pressurising and for filling | 13 |

Heatable hose for transfer |

2 |

Feed pump (option) | 14a |

Stainless steel vessel (max. 6barg) |

3a |

Control cabinet for vibrator | 14b |

Magnetic laboratory agitator with agitation element |

3b |

Control cabinet for heating | 14c |

Heating plate |

4 |

Vibrator | 14d |

Temperature controller with pT 100 |

5 |

Pulsation chamber with membrane | 14e |

Heatable hose(electrical heating) |

6 |

Connection for vent, steam, waste and recycling | 14f |

Two nozzles for pressurising and for filling |

7 |

Nozzle plate | 15 |

Electrical heating for encapsulator head |

Short description

The encapsulation unit is best suited for the generation of microbeads using matrices where gelling is based on interfacial coacervation (e.g. alginate, carrageenan and the like). With the heatable feeding equipment you can use encapsulate melts with temperature up to 120°. Which of these or any other matrix might suit your specific needs depends on material you want to encapsulate (e.g. proteins or bacteria), what properties the beads should have (physical strength, permeability, edibility, etc.) and which regulations and guidelines you have to follow (Hygienic Guidelines for Food, FDA etc.).

Principle

A pressurized tank is used to generate a steady pulsation-free flow to the vibrating chamber. As an alternative, you can use a heatable pulsation-free transfer pump. The bead generating unit has 13 nozzles. The vibration is superimposed on the product feed in the vibrating chamber by means of a membrane (frequency and amplitude can be adjusted digitally). The generated drops can be observed by means of an LED-stroboscopic light as stationary chains of parallel drops. The stroboscopic light is automatically synchronised with the adjusted vibration frequency. Monodisperse beads of the size between 0.2 and 1.5mm can be generated.

Control cabinet for vibrator

Rack with display, four lines x 16 characters, programmable micro controller for vibration control and stroboscopic light, power supply between 110 V and 240 Volt, automatically adjusting

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download VAR E Thermal as PDF file (178KB) |