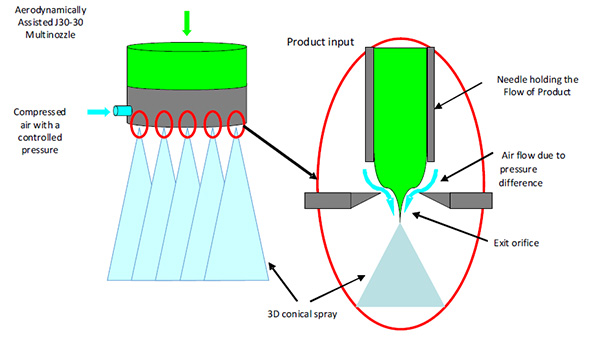

Encapsulation Unit – VARJ30-30

The VARJ30-30 is the aerodynamically assisted jetting equipment with 30 nozzles. The product enters through a central needle. The exit orifice, which is centrally in line with the axis of the needle, has been counter sunk externally. The counter sunk leads to the aero dynamical effect

that the jet has the smaller diameter when it is passing the orifice than the needle. The needle is enclosed in a pressure chamber with an exit through the orifice. The size of the drops is

determined by the product flow rate and the pressure inside the chamber. The product flow rate is typically controlled by a hyprecision syringe to be connected to the product nozzle. The pressure in the pressure chamber is controlled by the especially for the unit developed Nisco Pressure control unit consisting of a pressure sensor with digital indication. The pressure set point can be fixed with a potentiometer.

Principle of aerodynamically assisted jetting

Typical bead distribution: The beads were made with the nominal sized unit of 350 mm,

Typical bead distribution: The beads were made with the nominal sized unit of 350 mm,

resulting peak at 20 mm

Head of Encapsulation unit VAR J30-30

The unit consists of a product and a pressure chamber with a handle to fix it on the laboratory

support and 30 nozzles. The conversion can easily be conducted without tools.

Nisco Encapsulation Units conform to the European CE Safety Standards. If you want to work sterile you can proceed as follows: You can clean the nozzle with alcohol. The head as a whole can be sterilised in the autoclave.

Afterwards you can produce the beads within a laminar flow. If you want to work in a contained sterile manner, we offer the required extensions such as autoclavable sterile vessels.

Depending on your product you can use nitrogen. (Please be aware that the control cabinet is not designed for use in hazardous area) The bead generator with coaxial airflow is basically made of stainless steel 1.4435 (equivalent 316L) and can withstand most chemicals and high

temperatures, which make the unit very suitable for any disinfecting/cleaning method including

autoclave cleaning. As gaskets O-rings made of EPDM are delivered. For pharmaceutical or

medical applications the required material certificates are available.

The VARJ30-30 is supplied two set of 30 nozzles, (available sizes: 150, 200, 250, 350, 400, 500, 600, 700, 800, 900, 1000mm). This unique technology has the following advantages: The

reachable smallest particle is approximately 1:10 smaller than the needle diameter, depending on the physical properties of the product and on the requirements in regard of the particle homogeneity even smaller. So you can achieve very small particles with a minimised danger of clogging. So near homogenous particles around 20 micrometer are now in the reach with the VARJ30-30. For commercial applications check publications and patents on the technology.

Continuation Encapsulation Unit – VARJ30

The technology as it is applied in our VARJ30 has been published 1980 by Prof. Peter Walzel 1980. The concept of flow focussing was there since the dates going back to as far or even or further back to the 1960's

1968:

LLoyd Spielman and Simon L. Goren Improving Resolution in Coulter Counting by

Hydrodynamic Focusing Department of Chemical Engineering, University of California, Berkley

Journal of Colloid and Interface Science 26, 176-182

1983:

The concept has since been used heavily in the cytometry industry. Just to mention one example: US Patent 1983 4,408,877 vice for hydrodynamic focussing of a particlesuspension

in a liquid flow cytophotometer

1980:

P. Schmidt and P. Walzel, Zerstäuben von Flüssigkeiten Chem.-Ing.-Tech, 52 (1980) Nr. 4, S. 304-311.

1990:

P. Walzel, Zerstäuben von Flüssigkeiten Chem.-1ng.-Tech. 62 (1990) Nr. 12, S. 983-994

VCH Verlagsgesellschaft mbH, D-6940 Weinheim, 1990

1997:

A.M. Ganan Calvo and A. Barrero A Novel Pneumatic Technique to Generate Steady Capilary Microjets Aerosol Sci Vol 30, No. 1 pp. 118-125 1999

Since 1997 there were a lot of publications by various authors. There are also numerous current patents on the field of flow focussing. They were all published later than the articles listed above. For example US Patent 619953 by University Seville followed by numerous patents the following years.

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download Encapsulation Unit – VARJ30-30 as PDF-file |