Encapsulation Unit – VARJ30 Thermal

Heated Head and Air Pressure Vessel

The encapsulator’s heated air pressure vessel volume is equipped with an electrical heating

jacket. The jacket consists of an electrical heating and a Pt-100 sensor to control the temperature. Heating is 110V / 75W.

The Heatable Feeding System

The pressurised vessel is equipped with the air reducing station with which the needed air

pressure for the transfer to the nozzle can be adjusted.

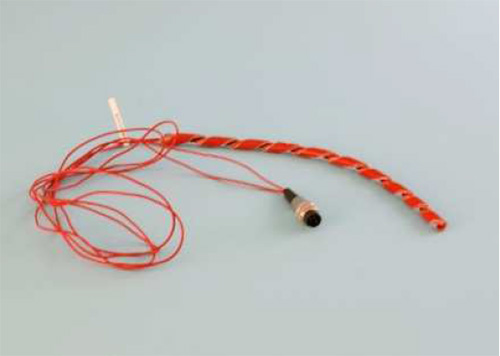

The vessel stands on top of a combined heating plate and agitator. The probe cable is connected to the agitator. The microcontroller controls the temperature within the vessel. The speed of the agitator can be adjusted on the system. An adjustable support insures a minimum distance between the head and the feeding system. The heatable hose is used for the supply of the matrix and the air to the nozzle.

- The material in contact with the product is silicone;

- The silicone core is a standard silicone hose and can be exchanged;

- The electrical heating is 24V/8W;

- The preheating time before a batch approx. 10 minutes.

Control cabinet for heating

The control cabinet for the auxiliary heating consists of the following components:

· On/off switch;

· Electronic temperature controller for air inlet and head;

· Power supply 110V to 240V

· Solid state relay for the electrical heating system;

· Power supply 24V for the heatable hose;

· 4 fuses;

· Plug for the encapsulator’s lower head, and the two transfer hoses

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download Encapsulation Unit – VARJ30 Thermal as PDF-file |