Var D Generation II Thermal/ Overview VAR D Generation II Thermal and Accessories

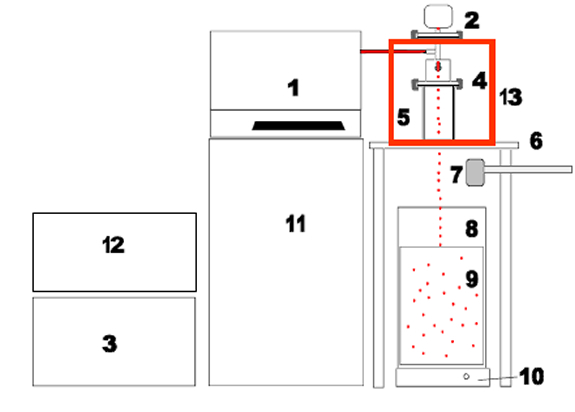

Legend:

1 Heated feeding system |

8 Beaker for hardening solution 9 Hardening solution with beads 10 Laboratory stirrer 11 Support for pump 12 Control cabinet for heating 13 Heating cylinder |

The encapsulation unit is best suited for the generation of microbeads using matrices, where

gelling is based on interfacial coacervation (e.g. alginate, carrageenan and the like). Which of

these, or any other matrix might suit your specific needs, depends on what you want to encapsulate (e.g. proteins or bacteria), what properties the beads should have (physical strength, permeability, edibility, and so on) and which regulations and guidelines you have to follow (Hygienic Guidelines for Food, FDA etc.). With the optional heating chamber you can also dropletise low melting products such as agarose.

The unit with its sophisticated multipurpose design and the flexible modular expandability has been tailored to the process developer’s requirements. The modular approach in the design allows to change the unit repeatedly according to the changing requirements and to combine components delivered by us with equipment and devices already available in your laboratory.

Control cabinets:

a) for the vibrator:

Rack with display, four lines x 16 characters, programmable microcontroller for vibration

control (choice ranges 160 to 3000Hz or 160 to 10'000 Hz). Power supply between 110 and

240 V AC automatically adjusting.

b) for auxilliary heating devices:

Power supply 240 V or 110 V adjustable; connections for the pT-100, and for the heated hoses.

Included in the scope of supply are: two nozzles as per your choice.

☞ The unit can be equipped with the coaxial or triple nozzle on request.

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download VAR D ThermalGeneration II as PDF file (270KB) |