Encapsulation with Nisco’s Electrostatic Accelerator

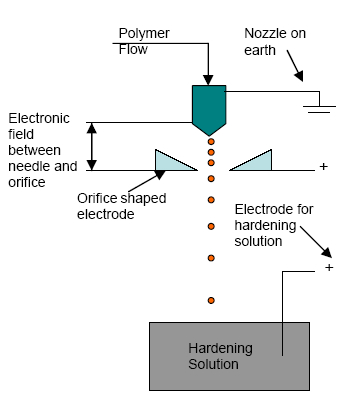

The new method is based on the use of the electrode, especially on its form. The ring electrode is installed between the nozzles and the hardening solution. The beads fall through the centre of the electrode.

Schematic drawing of electrostatic accelerator:

The following factors influence the bead size:

• size of needle

• distance between the needle and electrode

• voltage rate

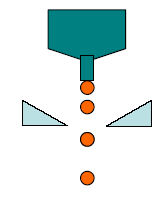

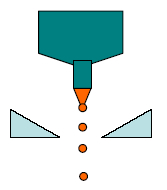

Two Different Types of Drop Generating

|

Low electrostatic field with standard nozzle holder |

|

|

High electrostatic field with conical jetting electrostatic accelerator resulting in small beads |

Advantage of electrostatic generator compared to the standard nozzle holder:

1. The bead size is independent from the level of the hardening solution.

2. With conical jetting the bead become essentially smaller than with conventional technology.

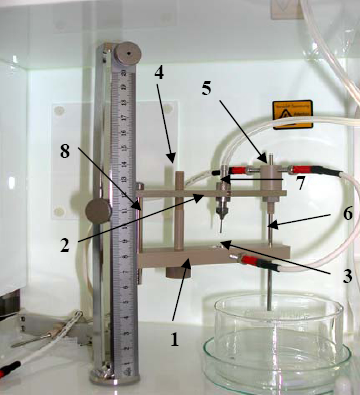

Legend and Material:

1. Lower holder (PEEK)

2. Upper holder (1.4301, stainless steel)

3. Orifice scoped electrode (1.4435)

4. Height adjustment screw

5. Isolator (PEEK)

6. Electrode bar (1.4435)

7. Adapter (stainless steel)

8. Guiding bar (1.4301, stainless steel)

Cables must be removed before autoclaving the device. Both types of drop generation can also be used in combination with coaxial nozzles available from Nisco.

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download PDF-File Encaps. with Nisco’s Electrostatic Accelerator |