Issue:170701Encapsulation Unit –VARCut2Go

Jet cutting is a very flexible technology to produce uniform particles from fluids which can freely flow though a nozzle. A lot of polymers like alginate, chitosan, pectinate, carrageenan cellulose derivate (CMC, SEC, CS), polyvinyl alcohol (PVA), and so on, in a certain concentration have higher viscosity than you can process with other technologies. You can produce a jet but the jet would not fall into drops for example by laminar jet-beak-up through vibration. Some polymers have elastic properties which dampen the superimposed vibration. So the jet would not fall into drops although the viscosity would be in the range which normally works out by laminar jet-break-up.

Especially when you add alumina or starch the viscosity goes up and in most cases the products can only be processed by mechanical cutting like with the Nisco VARCut2Go.

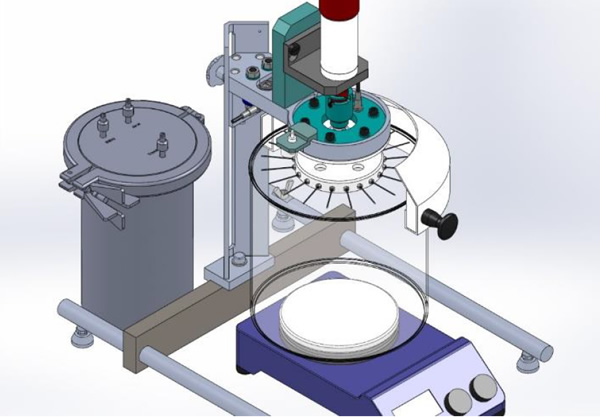

The unit has a rotating dished plate with 60 cutting tools regularly distributed over the circumference. By each rotation each cutting tool makes one cut that is to say we realise 60 cuts per revolution. The speed can vary between 100 and 10’000rpm.

The generated drops can be observed by means of an LED-stroboscopic light as a stationary chain of drops.

The unit is can be equipped with 1 up to 4 nozzles which work parallel in order to increase productivity.

In order to protect the operator the unit is in a safe transparent housing, the unit can only be started when the housing is closed and locked. It cannot be opened before the motor stands still.

The pulsation free feeding is realised by gear pump or pressurised addition system. We offer 2, 5 and 10L stainless steel vessels as feeding systems. Gear pumps can be used with a wide range of product properties. It is not recommended if you have abrasive particles in your product.

For the VARCut2Go a wide range of nozzles are available:

For matrix encapsulation (one product feed):

- Nozzles between 0.08mm and 2mm

For core shell beads:

- A wide range of coaxial nozzles (diameter of the outer nozzle between 0.3 and 2mm

For small beads:

The Aerodynamic option is available with the corresponding nozzles to produce a jet smaller than the nozzle size. Thus you can produce small matrix and coaxial beads.

The system can produce beads between 100 and 10’000 per seconds so you have quite a high productivity. Although you can produce smaller beads, most applications for VARCut2Go are between 0.4 and 5mm.

The bead generator is basically made of stainless steel 1.4435 (equivalent 316L) and can withstand most chemicals and high temperatures, which makes the unit very suitable for any disinfecting / cleaning method including autoclave cleaning. The gaskets are EPDM, Teflon or Viton depending on the application. Material certificates are available on request.

In Order to process melts we also offer heated feeding systems and a heated head as well as a 3 litre glass cylinder with jacket and circulation cooler for hardening the drops.

In Order to process melts we also offer heated feeding systems and a heated head as well as a 3 litre glass cylinder with jacket and circulation cooler for hardening the drops.

The resulting beads ideally are round. If the surface tension is not enough the form a round drop (before the hardening process), rounded cylindrical particles might be the result. With highly viscous feed this effect is very common.

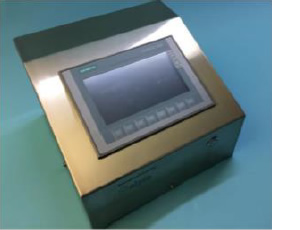

The unit is delivered with a digital control system and is visualised and operated through a coloured touch screen. Ethernet connection for enhanced communication function and software support is foreseen.

As an engineering oriented company we like to adapt the unit to your specific need.

![]() Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please use the Info-Form to ask for the adequate encapsulation system for your specific applications.

Please note: You need Acrobat reader to display the following PDF - Files.

| Download VARCut2Go as PDF file |